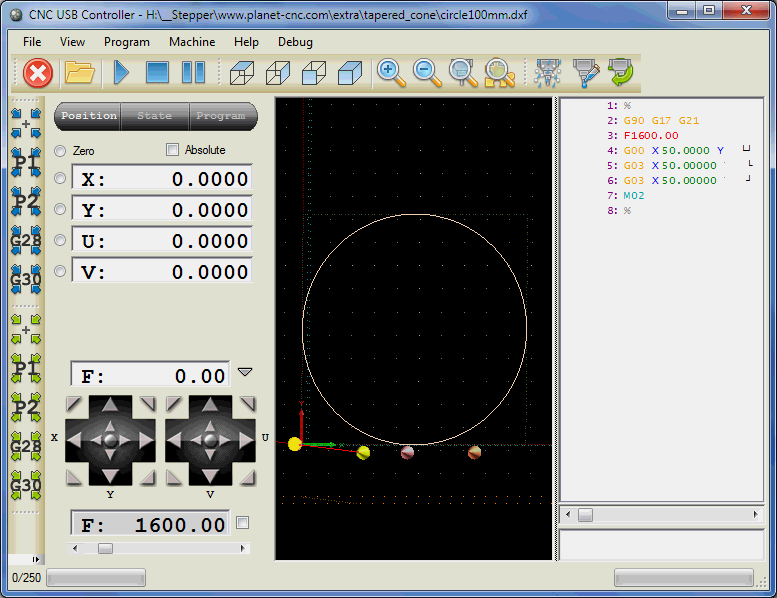

Cnc Usb Controller Activation

Nov 22, 2018 - Keygen usb cnc controller license activation code ※ Copy Link & paste in new tab: CNC USB Controller Crack, CNC USB. If you have registration key, open 'License activation' dialog and paste your registration key. If you have license data file (.dat,.lic or.zip) you can import it. There is no functional difference if using registration key or license data file. If you want to create backup copy of your license you can export it as license data file. Jan 18, 2016 - If you don't have a license you need to send us activation code and controller serial number. Activatemenu activaterequest.

Pluginmach3usb.dll for Mach3 (Ethernet and USB)

Copy Mach3usb.dll infolder C:mach3plugins (Or the correponding directory on your machine).

Then start Mach3 .They is a new dialog box 'Motion plugin detected'.

Start Mach3

Activate some axis

Indicate for eachaxis port and pin number and also polarity of signals DIR and STEP.

Stepper motor driverusually require positive pulse.

dir polarty change direction of rotation

Activate some outputs

Mach3 can control theSpindle from GCode with M3/M4/M5.

Indicate what pincontrol the spindle relay if available. Output #1 is normally used.

Others outputs can bedefined and configured (HiStep has 12 outputs)

Enable are signalswhich are always activated by Mach3 when not in EStop mode.

Associate Output#1with the spindle command

Standard signals(Spindle , Flood, Mist) can be configured to control the outputs#N

Configure some inputs

Standard functions ofMach3 (Limits ,Home ) can be associated to input pins of HiStep.

Enter port 1 and pin(10-13 , 15).

Configure speed andacceleration

Select units in 'Config/Select native units'

Press 'Save axissetting' for every axis

Then OK

Slave Axis

Slave axis are handled also by the plugin

Send the wholeconfiguration to card

Press'Reset ' in Mach3 to enter or leave EStop mode and also to upload any required configuration to the card ( ie pins , speed and al other)

Activate keyboard jogin Mach3

Activate motor movement with keyboard jog

Enter MDI commandsand run GCode directly

Type 'G0X10' in MDI tab.

Type M3/M5 to controlspindle output

Look current steppercoordinates

Stepper motorcoordinates are maintained by the CNC card . They are displayed in Mach3 mainwindow.

Check io status inDiagnostic tab

Configure limitswitch and home

Limit switch blockany movement when activated

Use Home command

RefAllHome'command the specified action :

-Jog to the homeswitch until activated

-return in theopposite directiion until desactivated

Important parameter are homingspeed (fast or slow ) and homing direction

Use PWM output

The 32 bit and later adapter support PWM output (for spindle speed)

Go in config/pulley ratio to set maximum speed of spindle. (the PWM output will be 100% duty cycle at maximum speed)

Go in config/port and pins/motor pins to select PWM pin (Spindle pin)

Set spindle pin number and optionally 'Active Low' to revert signal.

Test spindle :

In MDI G-code , type M3 S300 (speed 300RPM

Or use interface to set spindle speed and on/off state .

Configure plugin

Software interpolation (32 bit adapter only) :

Software microstep produce more precise time control, specially at low speed . Enter N>1 as software microstep and multiply by N your Mach3 StepPer setting All movement will be lot more smooth (and low noise) .

When using software microstep multiplicator, Mach3 motion planner will work exacly as if the StepPer parameter was much higher than the physical one, without reducing maximum speed and frequency!

Press EStop from inactive to active (or twice if already active) before tuning motors.

Plugin type and port number :

full motion plugin(Mach3 use the plugin for all motor movement)

IO Extender (Mach3still use parallel port for motion but use the plugin for some of it'sinput/output. Must select a available parallel port number.

A second port number (default 2) may be entered for dual port USB card.

Restart Mach3 if anychange.

Auto-off on enable signals:

The adapter can automatically cut enable signals when no move after 0.5 second (approx. default), this is very convenient and should be checked.

for 32bit card : auto-off duration can be set

USB and Ethernet :

USB : Allow USB connection

Ethernet : Allow Ethernet connection

IP address : adapter IP address

Auto IP : Allow auto detect network adapter

Press EStop to disconnect/reconnect for any change USB/Ethernet or IP address.

Ethernet IP update and detection

From plugin configuration dialog box press 'Ethernet' button

This open the network card update tool

Select a card from the list (not required if only 1 card , first entry is taken )

Fill in the modified parameter and press 'Update' button.

How to delete folder from desktop. The card then reboot automatically with new settings .

Note: If the IP address is incorrect , the update tool will still work because it does not use the IP address to talk to the card.

Use PROGRAM PAUSE / PROGRAM STOP

Cycle Start : Start a GCode program

Feed Hold : Pause GCode program

Stop : Stop GCode program

With the plugin , Stop is immediate effect with flushing data buffer , Hold (or pause) take a few second because movement continue until the data buffer come empty .

When using 'Feed Hold' , press 'Regen toolpath' before 'Run'. This will ensure a correct continuation of GCode program.

| Adapter | Index input pin |

| Combi MZ USB+Ethernet | pin 12 |

| USB V2 | pin 13 |

Firmware update (32 bit card only)

Enable alternate firmware : if an alternate firmware has been loaded , enable the card to use it (instead of the default factory ) .

Firmware tool : allow to change the alternate firmware

Note : the card always keep protected the initial firmware, and boot on the initial firmware when restarted ! Then switch to alternate firmware only on request of Mach3.

Sometime , they maybe a time delay between the current GCode line displayed by Mach3 and the one executed on the card. They maybe also a delay of PROGRAM STOP / PROGRAM PAUSE. This is due to internal command buffer of the USB or Ethernet card. You can reduce the buffer size in plugin configuration , by entering a value <> 0 in BufferSize (KB) setting . 8KB is a reasonable value.

Pluginmach3usb.dll for Mach3 (Ethernet and USB)

Copy Mach3usb.dll infolder C:mach3plugins (Or the correponding directory on your machine).

Then start Mach3 .They is a new dialog box 'Motion plugin detected'.

Start Mach3

Activate some axis

Indicate for eachaxis port and pin number and also polarity of signals DIR and STEP.

Stepper motor driverusually require positive pulse.

dir polarty change direction of rotation

Activate some outputs

Mach3 can control theSpindle from GCode with M3/M4/M5.

Indicate what pincontrol the spindle relay if available. Output #1 is normally used.

Others outputs can bedefined and configured (HiStep has 12 outputs)

Enable are signalswhich are always activated by Mach3 when not in EStop mode.

Associate Output#1with the spindle command

Standard signals(Spindle , Flood, Mist) can be configured to control the outputs#N

Configure some inputs

Standard functions ofMach3 (Limits ,Home ) can be associated to input pins of HiStep.

Enter port 1 and pin(10-13 , 15).

Configure speed andacceleration

Select units in 'Config/Select native units'

Press 'Save axissetting' for every axis

Then OK

Slave Axis

Slave axis are handled also by the plugin

Send the wholeconfiguration to card

Press'Reset ' in Mach3 to enter or leave EStop mode and also to upload any required configuration to the card ( ie pins , speed and al other)

Activate keyboard jogin Mach3

Activate motor movement with keyboard jog

Enter MDI commandsand run GCode directly

Cnc Usb Controller License Free

Type 'G0X10' in MDI tab.

Type M3/M5 to controlspindle output

Look current steppercoordinates

Stepper motorcoordinates are maintained by the CNC card . They are displayed in Mach3 mainwindow.

Check io status inDiagnostic tab

Configure limitswitch and home

Limit switch blockany movement when activated

Use Home command

RefAllHome'command the specified action :

-Jog to the homeswitch until activated

-return in theopposite directiion until desactivated

Important parameter are homingspeed (fast or slow ) and homing direction

Use PWM output

The 32 bit and later adapter support PWM output (for spindle speed)

Go in config/pulley ratio to set maximum speed of spindle. (the PWM output will be 100% duty cycle at maximum speed)

Go in config/port and pins/motor pins to select PWM pin (Spindle pin)

Set spindle pin number and optionally 'Active Low' to revert signal.

Test spindle :

In MDI G-code , type M3 S300 (speed 300RPM

Or use interface to set spindle speed and on/off state .

Configure plugin

Software interpolation (32 bit adapter only) :

Software microstep produce more precise time control, specially at low speed . Enter N>1 as software microstep and multiply by N your Mach3 StepPer setting All movement will be lot more smooth (and low noise) .

When using software microstep multiplicator, Mach3 motion planner will work exacly as if the StepPer parameter was much higher than the physical one, without reducing maximum speed and frequency!

Press EStop from inactive to active (or twice if already active) before tuning motors.

Plugin type and port number :

full motion plugin(Mach3 use the plugin for all motor movement)

IO Extender (Mach3still use parallel port for motion but use the plugin for some of it'sinput/output. Must select a available parallel port number.

A second port number (default 2) may be entered for dual port USB card.

Restart Mach3 if anychange.

Auto-off on enable signals:

The adapter can automatically cut enable signals when no move after 0.5 second (approx. default), this is very convenient and should be checked.

for 32bit card : auto-off duration can be set

USB and Ethernet :

USB : Allow USB connection

Ethernet : Allow Ethernet connection

IP address : adapter IP address

Auto IP : Allow auto detect network adapter

Press EStop to disconnect/reconnect for any change USB/Ethernet or IP address.

Ethernet IP update and detection

From plugin configuration dialog box press 'Ethernet' button

This open the network card update tool

Select a card from the list (not required if only 1 card , first entry is taken )

Fill in the modified parameter and press 'Update' button.

The card then reboot automatically with new settings .

Note: If the IP address is incorrect , the update tool will still work because it does not use the IP address to talk to the card.

Use PROGRAM PAUSE / PROGRAM STOP

Cycle Start : Start a GCode program

Feed Hold : Pause GCode program

Stop : Stop GCode program

With the plugin , Stop is immediate effect with flushing data buffer , Hold (or pause) take a few second because movement continue until the data buffer come empty .

When using 'Feed Hold' , press 'Regen toolpath' before 'Run'. This will ensure a correct continuation of GCode program.

| Adapter | Index input pin |

| Combi MZ USB+Ethernet | pin 12 |

| USB V2 | pin 13 |

Firmware update (32 bit card only)

Enable alternate firmware : if an alternate firmware has been loaded , enable the card to use it (instead of the default factory ) .

Firmware tool : allow to change the alternate firmware

Note : the card always keep protected the initial firmware, and boot on the initial firmware when restarted ! Then switch to alternate firmware only on request of Mach3.

Sometime , they maybe a time delay between the current GCode line displayed by Mach3 and the one executed on the card. They maybe also a delay of PROGRAM STOP / PROGRAM PAUSE. This is due to internal command buffer of the USB or Ethernet card. You can reduce the buffer size in plugin configuration , by entering a value <> 0 in BufferSize (KB) setting . 8KB is a reasonable value.